(1) The manufacturing process of the spiral welded pipe determines that its residual stress is relatively large. According to relevant foreign records, some are even close to the yield limit. The residual stress of the straight seam submerged arc welded pipe is close to zero due to the pipe expansion process. Improper heating will be the cause of scraps such as cracks, folds and eccentric pain on the inner or outer surface of the tube blank.

(2) It is difficult to track the welding of spiral welds and ultrasonic online detection and tracking. Therefore, the probability of weld defects exceeding the standard is higher than that of straight seam submerged arc steel pipes. The key to this heating operation is to uniformly heat the billet to a temperature suitable for processing. Since the perforation has a great influence on the quality, that is to say, the temperature during the bending process is an important condition affecting the quality, so the temperature of the blank during the perforation process is generally controlled.

(3) Most of the misalignment of the spiral welded pipe is 1.1 to 1.2 mm. According to international practice, the misalignment is less than 10% of the thickness. For example, when the wall thickness of the pipe is small, the misalignment cannot meet the requirements, and the straight seam submerged arc welded pipe has no such problem. In the production process of the spiral welded pipe, since the primary processing is carried out in a hot state, the heating operation is a very important process to determine the quality of the product. The hot blast furnace for heating is divided into two types: heating furnace and reheating furnace according to their effects; the former is used to heat the blank from normal temperature to the processing temperature; the latter is used to reheat the blank to the necessary processing during the processing.

(4) Compared with the straight seam submerged arc welded pipe, the flow line of the spiral weld is poor, and the stress concentration is serious. How to control the quality of spiral welded pipe? The piercing temperature of the blank varies depending on the raw material. But most of the thermal expansion welded pipes are around 1200 ° C, and the temperature is slightly lower when the carbon content and other alloying elements are large. The second key to the heating operation is to minimize the amount of scale. Especially in the hot kneading elbow, the thermal expansion welded pipe starts from the tool life and the surface quality of the kneaded pipe, and the requirements are severe.

(5) The heat-affected zone of the spiral submerged arc welded steel pipe is larger than that of the straight seam submerged arc welded steel pipe, and the heat-affected zone is the weak link in the quality of the welded pipe. There are many types of hot blast stoves, but the most commonly used is the annular heating stove. This heating furnace has an annular furnace bottom, which can be slowly transformed, and the billet is charged along the diameter direction of the furnace bottom from the inlet, and when it is reversed to the outlet, it can be heated and soaked to a regular temperature.

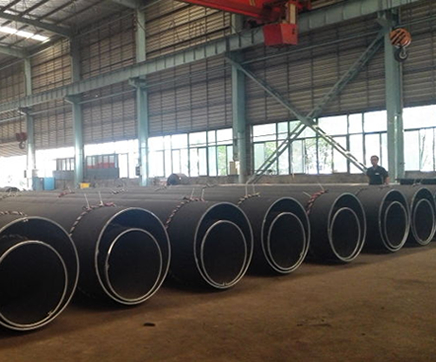

(6) The geometric dimensional accuracy of the spiral welded pipe is poor, which brings certain difficulties to on-site construction (such as counterparts and welding). Compared with the straight seam submerged arc welded steel pipe, the spiral welded pipe has certain deficiencies in quality. There are seven summarized below for your reference.

(7) With the same diameter, the thickness of the spiral seam welded steel pipe is much smaller than that of the straight seam submerged arc welded steel pipe.